Need any help or advice?+44 (0)1782 454499

VIDEOS IN THIS SERIES

This video is part 3 of a 3 part series:PRODUCTS USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

VACUUM BAGGING CONSUMABLES

COMPONENT MATERIALS

TOOLS & EQUIPMENT

VIDEO TUTORIAL

Moulding Complex Hollow Carbon Fibre Parts with Silicone Intensifiers

Advanced level composites video tutorial outlining the process of laminating and vacuum bagging a complex, hollow carbon fibre part, including the use of silicone intensifiers to achieve proper consolidation in challenging areas.

As well as the main moulding, the guide also covers bonding in the internal structure including longerons, bulkheads, and spars to complete the fuselage for a flying wing drone.

WHAT YOU WILL LEARN

Overview

- What materials and laminating process are best for complex, hollow structures.

- How to use silicone intensifiers in difficult-to-bag areas.

- How to use 'laps' to provide strength across mould sections, where access is restricted.

- Techniques for mould closure without trapping 'laps'.

- How to vacuum bagging hollow components.

- How to easily create an ultra lightweight sandwich panel.

- How to bond aircraft internal structures.

Material Process & Selection

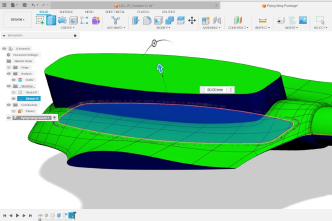

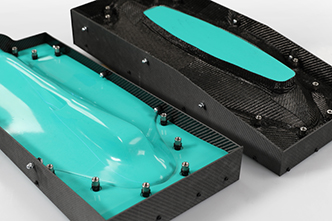

To create a hollow carbon fibre part, a split moulds is essential. This drone fuselage uses a four-piece mould made from XT135 tooling prepreg, including MB1 mould bushes for alignment and secure clamping.

Although other composites processes, including basic hand lamination, would be possible, complex components requiring split-moulds are easiest to produce using prepreg carbon fibre which allows for accurate cutting of the reinforcement, including overlapping sections to make the join between mould sections, known as ‘laps’.

Sharp, detailed areas like the wing’s trailing can be very difficult to vacuum bag, potentially leading to bridging and pinholes or poor consolidation. Silicone intensifiers can be used in these areas to simplify bagging and ensure proper consolidation.

STEP-BY-STEP GUIDE

1. Preforming Intensifiers

Silicone intensifiers are normally co-cured alongside the prepreg laminate on first use but in this example, the intensifier will be preformed and cured without any reinforcement in the mould. Doing so means that the shape of the intensifier does not allow for any material thickness, thereby exerting additional pressure on these areas when the mould halves are clamped together, however, this is only possible on thin laminates of 1mm or less.

Release film is applied to the mould surface to prevent silicone adhesion. INTENSIL 40 is moulded into the basic desired shape, trying to avoid air voids in the silicone. The mould is closed and the silicone is shaped from the inside to ensure good consolidation and to feather the edges of the intensifier, which could otherwise cause bag bridging of their own.

The silicone is then covered in release film, vacuum bagged in the normal way and cured at 120°C for one hour.

Once cured, the silicone intensifiers, which are reusable indefinitely, can be removed from the mould and are ready for use.

2. Cutting Templates and Lap Strategy

Templates are made by covering the mould's surface with masking tape, marking cut positions, and transferring these to a flat backing material which is cut to shape to make the basic templates.

To tie the two halves of the component together, ‘laps’ can be used. This is where the reinforcement on one side of the mould extends past the edge of the mould, whilst the corresponding ply on the other side of the mould is reduced accordingly. When the mould halves are brought together, layers of reinforcement extend across the split line without affecting the laminate thickness in these areas. This approach ensures strong, seamless joints without requiring internal access for taping.

3. Reinforcement Kit Cutting

Use the templates to cut the kit of prepreg carbon fibre reinforcement.

The kit for the first ply is cut exactly to template because this ply will finish flush with the edge of the mould. When cutting the kit for the second ply, adjust the templates to include the lap strategy, extending some templates and shortening the opposing templates by the same amount.

The silicone intensifiers can also be used as templates and should be extended appropriately.

4. Laminating the Prepreg

Before starting to laminate the prepreg reinforcement into the mould, ensure that the moulds are correctly prepared with a suitable release agent, such as Easy-Lease CR1 Chemical Release Agent.

Laminate the first ply into the upper and lower halves of the mould paying close attention to avoid avoiding bridging of the laminate, especially in tight corners. The reinforcement is then carefully trimmed flush with the perimeter of the mould using a scalpel, being careful to present a flat blade to the mould’s flange in order to avoid damaging it.

The second plies are then laminated into the mould. On one side, the reinforcement will extend 10mm past the edge of the mould, on the other side, it will be 10mm short of the edge.

The barriers are attached to the lower half of the mould and the reinforcement for the wing roots, which includes a 10mm extension lap all round, is laminated into place.

5. Positioning Intensifiers and Closing the Mould

The silicone intensifiers for the wing root are wrapped in release film to make them easy to remove and to prevent degradation of the silicone during the cure. They are then placed firmly against barriers and the top lap is folded over ready for mould closure.

The extended lap around the perimeter of the mould is gently folded in ready for closure and can be held in position using some flash release tape.

Carefully bring the two mould halves together, looking where possible to ensure that the laps are still correctly held folded into the cavity within the component. Once the moulds are together, the release tape can be slid out, allowing the laps to unfold up onto the opposite side of the mould. Check no laps are trapped between the mould halves and clamp the moulds together through the mould bushes.

6. Vacuum Bagging and Cure

Bagging hollow parts requires a vacuum bag that is sufficiently large to allow it to reverse in on itself inside the mold. Great care must be taken to ensure that the bag is following all of the contours without bridging or stretching, although this is made much simpler with the intensifiers taking care of all of the most difficult areas.

Once bagged, the part is loaded into the oven and cured using the standard XC110 cure cycle under full vacuum.

7. Demould and Trim

Once cured, the barriers are removed, the mould sections unbolted and the part can be removed from the mould.

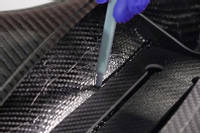

Remove the resin flash and fettle the edge smooth using Perma-Grit sanding blocks and abrasive paper. The hole for the spar tube is cut using a Perma-Grit rotary tool.

8. Internal Structure

Components for the internal structure like longerons, floor and ribs are made from lightweight carbon fibre sandwich panel. The panel is made using a single ply of 210g prepreg carbon fibre either side of a layer of 3mm Rohacell PMI foam, vacuum bagged against a glass sheet using the standard XC110 cure cycle.

The components are then cut out of the panel on a 3-axis CNC for precision but could also be easily cut by hand. Components taking a higher load, like the motor-mount, are cut from solid 2mm carbon fibre sheet.

Surfaces to be bonded are prepared using abrasive paper and then degreased using 100% IPA bond preparation wipes.

The structure is bonded in place using Permabond ET4528 (or ET5429 if a longer working time is required) which will provide an extremely high strength bond between carbon fibre components, even on small surface area ‘edge bonds’.

9. Clearcoat Paint Finish

Prior to paint, the part is keyed with 400 grit abrasive paper and thoroughly cleaned and degreased using soapy water.

A single coat of Fantom Clear CX, followed by a light flattening and a final finishing coat results in an exceptional satin finish whilst adding only around 10g of weight.

DISCUSSION (8)

Please share any questions or comments you may have about this video tutorial.

In our testing, and on paper, it’s practically unbeatable so you can’t go wrong. However, sometimes it can be better then it needs to be (so, a cheaper adhesive might be good enough). But, if you don’t want to try to work that out then ET5428 cannot be outbonded!

Honestly, we’ve not tried this but it could be possible. However, silicone is inexpensive (cheaper than 3D print, probably) and does the job so well (squishy, able to conform) that I think it’s unlikely that a 3D print would work as well. Possibly TPU, but the INTENSIL compound is so quick, easy and effective that unless you can’t get hold of some, it’s probably hard to beat with any kind of 3D print.

Exactly that. At just 2 plies of 210g it really wouldn’t make any difference, but anything more (even including swapping the second ply to something heavier) and we would have done.

Your understanding is good. It’s true that silicone has a high CTE and so can be used to create pressure in its own right, however, in order to do this the mould geometry needs to constrain the silicone on most faces to a large extent, without this, the expansion of the silicone has little effect. But, with constraint, it can be very effective.

Yes, peel ply can be used to prevent the need for keying before bonding, however, peel ply absorbs some resin and on such a thin laminate there’s no resin to spare and so you’ll end up with slightly dry reinforcement in those areas. On thicker laminates though, peel ply is a good time saver prior to secondary bonding.

To do this in one piece with infusion would be very tricky, not impossible, but it's definitely easier with prepreg in this case. If you were to infuse it would be best to make the top and bottom separately and then bond them after curing.

Even in this project, which went very well, there can still be some micro pinholes in a couple of areas (which is normal, even on the best made parts). A skim over with a clear resin such as XCR is a good fix, or a clear coat (as used in this video) should also overcome them.

Nice little trick that may work well if you are struggling to keep the laps in position.

LEAVE A COMMENT OR QUESTION

PRODUCTS USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

VACUUM BAGGING CONSUMABLES

COMPONENT MATERIALS

TOOLS & EQUIPMENT

DISCUSSION (8)

Please share any questions or comments you may have about this video tutorial.

In our testing, and on paper, it’s practically unbeatable so you can’t go wrong. However, sometimes it can be better then it needs to be (so, a cheaper adhesive might be good enough). But, if you don’t want to try to work that out then ET5428 cannot be outbonded!

Honestly, we’ve not tried this but it could be possible. However, silicone is inexpensive (cheaper than 3D print, probably) and does the job so well (squishy, able to conform) that I think it’s unlikely that a 3D print would work as well. Possibly TPU, but the INTENSIL compound is so quick, easy and effective that unless you can’t get hold of some, it’s probably hard to beat with any kind of 3D print.

Exactly that. At just 2 plies of 210g it really wouldn’t make any difference, but anything more (even including swapping the second ply to something heavier) and we would have done.

Your understanding is good. It’s true that silicone has a high CTE and so can be used to create pressure in its own right, however, in order to do this the mould geometry needs to constrain the silicone on most faces to a large extent, without this, the expansion of the silicone has little effect. But, with constraint, it can be very effective.

Yes, peel ply can be used to prevent the need for keying before bonding, however, peel ply absorbs some resin and on such a thin laminate there’s no resin to spare and so you’ll end up with slightly dry reinforcement in those areas. On thicker laminates though, peel ply is a good time saver prior to secondary bonding.

To do this in one piece with infusion would be very tricky, not impossible, but it's definitely easier with prepreg in this case. If you were to infuse it would be best to make the top and bottom separately and then bond them after curing.

Even in this project, which went very well, there can still be some micro pinholes in a couple of areas (which is normal, even on the best made parts). A skim over with a clear resin such as XCR is a good fix, or a clear coat (as used in this video) should also overcome them.

Nice little trick that may work well if you are struggling to keep the laps in position.

LEAVE A COMMENT OR QUESTION

100% SECURE

PAYMENT METHODS

Easy Composites EU B.V., registered in the Netherlands 73601195. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.