Need any help or advice?+44 (0)1782 454499

Specification

Fabric Specification

| Fibre Specifics | Toray T700 12k | |

|---|---|---|

| Colour | Black | |

| Fibre Orientation | 0, 90 | |

| Type | Component Prepreg | |

| Resin Matrix | Epoxy | |

| Weave | 1 x 1 Plain | |

| Format | Woven Fabric | |

| Filament Count | 12k | |

| Fibre Type | Carbon Fibre | |

| Ends | 0.55 | cm |

| Picks | 0.56 | cm |

Weight and Dimensions

| Width | 1000 | mm |

|---|---|---|

| Consolidated Thickness | 0.12 | mm |

| Areal Weight | 88 | g/m² |

| Resin Weight | 48 | % |

Fibre Properties

| Min Cure Temp | 80 | °C |

|---|---|---|

| Max Cure Temp | 120 | °C |

| Max Service Temp | 130 | °C |

| Filament Diameter | 7 | µm |

| Out-life (at 20°C) | 30 | Days |

| Freezer-life (at -18°C) | 12 | Months |

| UV Resistance | Good |

General Properties

| Gross Weight | 0.38 | kg |

|---|---|---|

| Brand | XPREG |

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Prepreg Product - IMPORTANT!

Uncured prepreg materials are stored at -20°C and are shipped still frozen from our facility. This prepreg has an 'out-life' of at least 30 days at room temperature and so typical delivery times will still leave plenty of safe 'out-life' remaining.

During summer months or periods of hot weather, it is recommended to order prepregs at the start of the week (Monday or Tuesday) to avoid adding extra shipping days over the weekend.

Unless you plan to use the product immediately, it should be placed into frozen storage as soon as possible on receipt.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

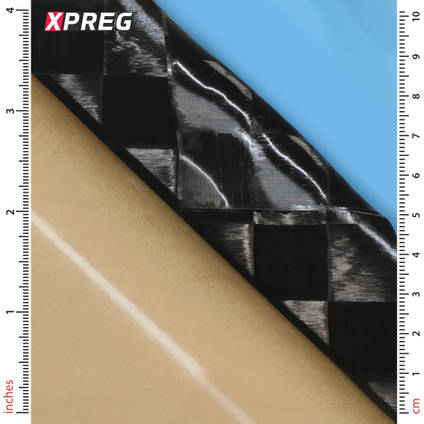

XC130 88g 18mm Spread-Tow Prepreg Carbon Fibre (1000mm)

- XPREG

- XC130-CST12PW-88(1000)-1

- No reviews

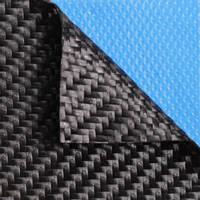

Ultra-lightweight prepreg reinforcement using our XPREG® XC130 resin system but 100% compatible with our XC110 system. This is an uncured prepreg material and requires an oven or autoclave to cure it.

This 88g spread-tow reinforcement is typically used as a surface ply on lightweight laminates, such as wing-skins, but can also provide an eye-catching appearance on cosmetic or structural components, on its own or combined with other reinforcements.

This prepreg reinforcement is 1m (1000mm) wide and sold in a choice of prepacked roll lengths.

PRODUCT VERSIONS

Roll Length

AVAILABILITY:7 in stock available for immediate shipping

40 more can built in 2-3 days

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

XPREG® XC130 is an epoxy-based component prepreg carbon fibre system with a 130°C maximum service temperature. Although XC130 is usually recommended only for autoclave cure, on this 88g spread-tow it also delivers a pin-hole free 'visual quality' surface finish when cured correctly in an oven under vacuum pressure only (i.e. out-of-autoclave).

This toughened resin system offers excellent mechanical properties whilst its clear formulation and excellent surface finish make it suitable for the manufacture of visual quality carbon fibre components. The XC130 resin system has a long out-life with an intermediate tack level making for easy handling and laminating whilst its variable cure temperature from 80°C allows a wide range of mould systems to be used.

Combining with Other Prepreg Reinforcements

XC130 is fully compatible with our XA120 adhesive film, as well as XC110 out-of-autoclave system, and other XC130 autoclave cure prepregs.

When oven curing out of autoclave

This 88g spread-tow XC130 prepreg can be used to create a pin-hole free, visual quality surface ply without an autoclave, instead requiring only accurate temperature control (ramp and soak) and maximum vacuum bag pressure.

In order to achieve a pin-hole free surface finish when using the 88g spread tow out-of-autoclave, it should be combined with our XC110 (out-of-autoclave) prepregs.

When curing in an autoclave

When this 88g spread-tow will be cured in an autoclave, it should be used on its own or combined with any of our XC130 (autoclave cure) prepregs. Doing so will maintain the higher 130°C Tg and higher mechanical properties of the XC130 system.

Typical Uses

This 88g spread-tow carbon fibre is suitable for fully structural, as well as cosmetic applications. Given its extremely low weight of just 88gsm, it is often used in particularly lightweight applications like wing skins on RC models, or in fishing pole repairs.

This spread-tow carbon fibre prepreg has 18mm wide carbon 'tows' arranged in a plain weave pattern, creating the checkerboard appearance of plain weave carbon fibre but in a much larger pattern. The large pattern print of spread-tow means it is also used as a distinctive and eye-catching surface ply on cosmetic components like vehicle panels, interior trim and sports equipment ranging from hockey sticks to hydrofoils.

- Wing skins on RC planes

- Surface ply on vehicle panels

- Interior trim

- Fishing pole repairs

- Skis, snowboards, foils, kiteboards

How to Buy

All XPREG® prepregs are stored on site in our freezers. To reduce handling time and allow same-day dispatch, prepregs are available in pre-cut roll lengths. Choose the roll length you require from the options at the top of the page. When ordering a full roll of material, the option shows the typical roll length but please allow for length variance of plus or minus 1m which has already been factored into the low unit price of our full length rolls.

Your XPREG® prepreg is sealed in air-tight packaging and will ship from us still frozen. Please see the transport tab for further details and important information about delivery.

The Sample Pack Contains two 400x300mm (15.7x11.8") pieces of prepreg.

Further Information

Curing

XC130 can be cured from 80°C to 130°C, although service temperature will be determined by the final cure temperature. For out-of-autoclave cure, a precisely controlled stepped temperature cure cycle is required. See the Technical Datasheet for full details on recommended cure cycles.

Storage and Handling

The ‘out-life’ of XC130 is 6 weeks at 20°C.

When not in use, XPREG® prepregs should be kept frozen at -18°C (0°F) in sealed plastic packaging, in which condition the freezer-life is 12 months. When ready to use, the material should be removed from the freezer and allowed to thaw fully to room temperature before being removed from the packaging. See technical datasheet for full details storage and handling.

XPREG® XC130 is an epoxy-based component prepreg carbon fibre system with a 130°C maximum service temperature. Although XC130 is usually recommended only for autoclave cure, on this 88g spread-tow it also delivers a pin-hole free 'visual quality' surface finish when cured correctly in an oven under vacuum pressure only (i.e. out-of-autoclave).

This toughened resin system offers excellent mechanical properties whilst its clear formulation and excellent surface finish make it suitable for the manufacture of visual quality carbon fibre components. The XC130 resin system has a long out-life with an intermediate tack level making for easy handling and laminating whilst its variable cure temperature from 80°C allows a wide range of mould systems to be used.

Combining with Other Prepreg Reinforcements

XC130 is fully compatible with our XA120 adhesive film, as well as XC110 out-of-autoclave system, and other XC130 autoclave cure prepregs.

When oven curing out of autoclave

This 88g spread-tow XC130 prepreg can be used to create a pin-hole free, visual quality surface ply without an autoclave, instead requiring only accurate temperature control (ramp and soak) and maximum vacuum bag pressure.

In order to achieve a pin-hole free surface finish when using the 88g spread tow out-of-autoclave, it should be combined with our XC110 (out-of-autoclave) prepregs.

When curing in an autoclave

When this 88g spread-tow will be cured in an autoclave, it should be used on its own or combined with any of our XC130 (autoclave cure) prepregs. Doing so will maintain the higher 130°C Tg and higher mechanical properties of the XC130 system.

Typical Uses

This 88g spread-tow carbon fibre is suitable for fully structural, as well as cosmetic applications. Given its extremely low weight of just 88gsm, it is often used in particularly lightweight applications like wing skins on RC models, or in fishing pole repairs.

This spread-tow carbon fibre prepreg has 18mm wide carbon 'tows' arranged in a plain weave pattern, creating the checkerboard appearance of plain weave carbon fibre but in a much larger pattern. The large pattern print of spread-tow means it is also used as a distinctive and eye-catching surface ply on cosmetic components like vehicle panels, interior trim and sports equipment ranging from hockey sticks to hydrofoils.

- Wing skins on RC planes

- Surface ply on vehicle panels

- Interior trim

- Fishing pole repairs

- Skis, snowboards, foils, kiteboards

How to Buy

All XPREG® prepregs are stored on site in our freezers. To reduce handling time and allow same-day dispatch, prepregs are available in pre-cut roll lengths. Choose the roll length you require from the options at the top of the page. When ordering a full roll of material, the option shows the typical roll length but please allow for length variance of plus or minus 1m which has already been factored into the low unit price of our full length rolls.

Your XPREG® prepreg is sealed in air-tight packaging and will ship from us still frozen. Please see the transport tab for further details and important information about delivery.

The Sample Pack Contains two 400x300mm (15.7x11.8") pieces of prepreg.

Further Information

Curing

XC130 can be cured from 80°C to 130°C, although service temperature will be determined by the final cure temperature. For out-of-autoclave cure, a precisely controlled stepped temperature cure cycle is required. See the Technical Datasheet for full details on recommended cure cycles.

Storage and Handling

The ‘out-life’ of XC130 is 6 weeks at 20°C.

When not in use, XPREG® prepregs should be kept frozen at -18°C (0°F) in sealed plastic packaging, in which condition the freezer-life is 12 months. When ready to use, the material should be removed from the freezer and allowed to thaw fully to room temperature before being removed from the packaging. See technical datasheet for full details storage and handling.

Specification

Fabric Specification

| Fibre Specifics | Toray T700 12k | |

|---|---|---|

| Colour | Black | |

| Fibre Orientation | 0, 90 | |

| Type | Component Prepreg | |

| Resin Matrix | Epoxy | |

| Weave | 1 x 1 Plain | |

| Format | Woven Fabric | |

| Filament Count | 12k | |

| Fibre Type | Carbon Fibre | |

| Ends | 0.55 | cm |

| Picks | 0.56 | cm |

Weight and Dimensions

| Width | 1000 | mm |

|---|---|---|

| Consolidated Thickness | 0.12 | mm |

| Areal Weight | 88 | g/m² |

| Resin Weight | 48 | % |

Fibre Properties

| Min Cure Temp | 80 | °C |

|---|---|---|

| Max Cure Temp | 120 | °C |

| Max Service Temp | 130 | °C |

| Filament Diameter | 7 | µm |

| Out-life (at 20°C) | 30 | Days |

| Freezer-life (at -18°C) | 12 | Months |

| UV Resistance | Good |

General Properties

| Gross Weight | 0.38 | kg |

|---|---|---|

| Brand | XPREG |

Unfortunately we do not stock any pre-pregs with a flexible resin. The only flexible resin we supply is our EF80 Flexible Epoxy Resin which is suitable for wet lay and vacuum bagged processes.

Unfortunately we do not stock any pre-pregs with a flexible resin. The only flexible resin we supply is our EF80 Flexible Epoxy Resin which is suitable for wet lay and vacuum bagged processes.

ASK YOUR OWN QUESTION

Customer Product Reviews for XC130 88g 18mm Spread-Tow Prepreg Carbon Fibre (1000mm)

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Prepreg Product - IMPORTANT!

Uncured prepreg materials are stored at -20°C and are shipped still frozen from our facility. This prepreg has an 'out-life' of at least 30 days at room temperature and so typical delivery times will still leave plenty of safe 'out-life' remaining.

During summer months or periods of hot weather, it is recommended to order prepregs at the start of the week (Monday or Tuesday) to avoid adding extra shipping days over the weekend.

Unless you plan to use the product immediately, it should be placed into frozen storage as soon as possible on receipt.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

RELATED PRODUCTS

RELATED PRODUCTS

100% SECURE

PAYMENT METHODS

Easy Composites EU B.V., registered in the Netherlands 73601195. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.