Need any help or advice?+44 (0)1782 454499

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

MATERIALS & CONSUMABLES

WOVEN CLOTHS

CUSTOMER GALLERY

Carbon Fibre Motorbike Fuel Tank Cover

Mattia has a 2008-2014 TM Racing 2 stroke bike. Making an entire carbon fibre fuel tank was beyond his knowledge and ability so he decided to make this part as a cover to achieve the same aesthetic look.

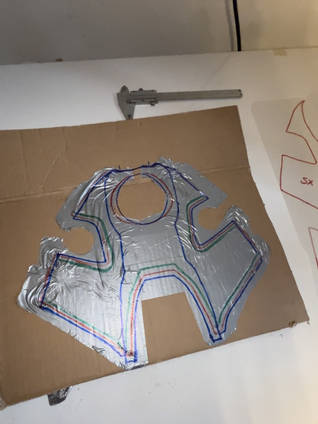

He started the project by making the pattern for the fabric with duct tape pieces and tracing out the size of the carbon fibre parts. Then moved on to covering and filling the areas and detail not to be replicated with filling wax and duct tape. Five layers of PVA mould release agent and 3 layers of mould release wax were applied to the tank.

Two plastic sheets were then used to lay up 0,4 square meter carbon fibre cloth with the same amount of weight of slow EL2 laminating resin. The sheet was then placed in a freezer, to stall the resin cure until needed. This method made the work easier and faster when laying down the carbon fibre onto the fuel tank. A thick layer of black XCR epoxy basecoat was brushed onto the tank and left until the B stage. The fibre was then defrosted and laid up in two layers of the 210g fibre on to the fuel tank.

The part was allowed to cure for 24 hours and started to cut carbon fibre excess off and trimmed and finishing the part. One layer of XCR Epoxy Resin Coating Resin was applied and the part was flatted going through 240 to 1200 grit sand paper, finally being polished with NW1 Supper Cutting Compound. The part was finished by applying clear lacquer to get a nice high gloss finish to the part.

ABOUT MATTIA MAZZOLI

Mattia is currently a student studying Automotive Engineering in Modena. With its rich history in car manufacturing and his history of motocross since an early age, he has been able to build on his experience by moving into composites.

Mattia started learning about composites about a year ago and following Easy Composites' tutorials has built his knowledge and skills such that he is now confident to make a variety of parts.

CONTACT INFORMATION

| @mattia__mazzoli |

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

MATERIALS & CONSUMABLES

WOVEN CLOTHS

ABOUT MATTIA MAZZOLI

Mattia is currently a student studying Automotive Engineering in Modena. With its rich history in car manufacturing and his history of motocross since an early age, he has been able to build on his experience by moving into composites.

Mattia started learning about composites about a year ago and following Easy Composites' tutorials has built his knowledge and skills such that he is now confident to make a variety of parts.

CONTACT INFORMATION

| @mattia__mazzoli |

100% SECURE

PAYMENT METHODS

Easy Composites EU B.V., registered in the Netherlands 73601195. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.