Need any help or advice?+44 (0)1782 454499

Specification

Weight and Dimensions

| Thickness | 50 | mm |

|---|---|---|

| Length | 250 | mm |

| Width | 250 | mm |

Product Data

| Colour | Green | |

|---|---|---|

| Density | 700 | kg/m³ |

Compatible With

| Compatible With | Epoxy | Yes |

|---|---|---|

| Compatible With | Polyester | Yes |

| Compatible With | Vinylester | Yes |

| Compatible With | Polyurethane | Yes |

| Compatible With | RTV Silicone | Yes |

| Compatible With | Prepregs | Yes |

Mechanical Properties

| Max Service Temp | 130 | °C |

|---|---|---|

| Chemistry / Material | Epoxy | |

| Compressive Strength | 50 | MPa |

General Properties

| Gross Weight | 2.19 | kg |

|---|

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

EB700 High Temperature Epoxy Tooling Board

- EB700-006-50

- No reviews

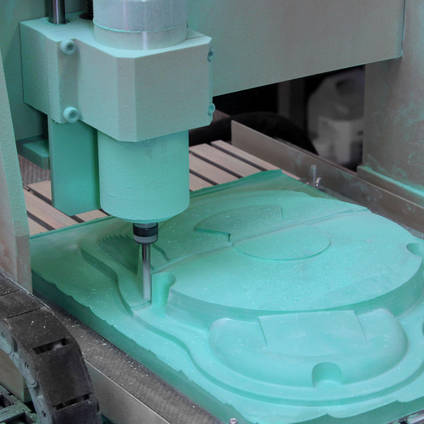

EB700 is a high quality 700kg/m³ epoxy tooling board recommended for CNC machining of highly accurate models, patterns or masters as well as low volume production tools/moulds. It offers excellent surface finish, stability and service temperature up to 130°C.

Epoxy tooling board is also highly recommended over PU tooling board when making patterns or moulds for use with epoxy-matrix prepregs.

Available to buy online in 50mm (2") and 100mm (4") thicknesses in a range of block sizes from 250 x 250mm up to 1500 x 500mm.

PRODUCT VERSIONS

Sheet Size

Thickness

AVAILABILITY:6 in stock available for immediate shipping

352 more can built in 2-3 days

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

EB700 is a high quality 700kg/m³ epoxy tooling board. This rigid epoxy tooling block is recommended for demanding applications for CNC machining of highly accurate models, patterns or masters as well as production tools/moulds.

Epoxy is the tooling board of choice for high temperature applications and is essential when making prepreg composite moulds or components where, at elevated temperature, this epoxy pattern material will not inhibit the cure of prepregs in the same way that polyurethane (PU) board will.

Typical Usese

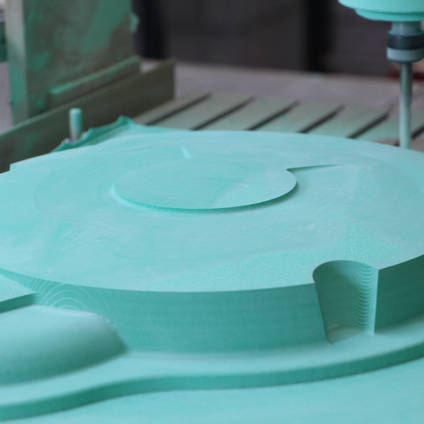

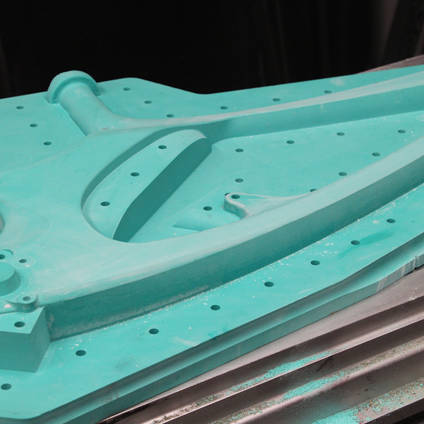

EB700 Epoxy Tooling Board can be used to produce highly accurate patterns and moulds. Patterns can be used to produce high volume composite moulds, including using prepreg tooling systems (with cure temperatures up to 130°C) and where dimensional stability is critical.

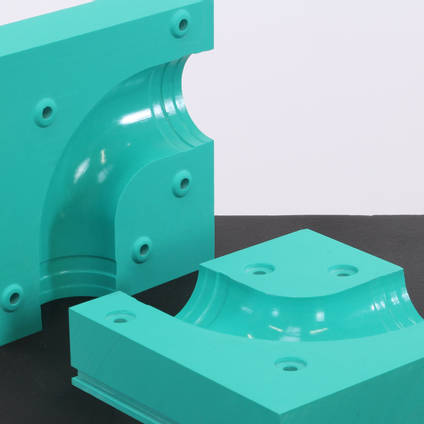

For smaller production runs EB700 can be used to produce the working mould itself. In this situation the machined mould - once suitably sealed and prepared - can be used as a mould/tool for the production of composite parts, including the manufacture of prepreg composite components (oven-only or autoclave cure).

Advantages

- High dimensional stability (low CTE)

- High temperature use (up to 130°C)

- Compatible with epoxy tooling and component prepregs

- Can be used directly as a mould/tool, including with prepregs

- Excellent internal consistency for a high quality surface finish

How to Buy

This board is available in 2 thicknesses; 50mm (2") and 100mm (4") and a range of sizes up to 500mm x 1500mm (19" x 59"), please select the thickness and block size you require from the drop-down menu at the top of the page.

Further Information

Bonding

For larger patterns or more diverse shapes, it is often necessary to bond multiple boards together or to cut and join a board to produce a hollow 'rough shape' prior to machining. In this case, EA700 Epoxy Tooling Board Adhesive can be used to bond the tooling board, resulting in machinable bond-line which matches the density and behaviour of the surrounding board.

Finishing

EB700 can be cut and shaped by hand however it is a high density material and better suited to CNC machining. Once machining is complete, the board can be finished to an excellent satin finish using a range of abrasive papers, typically ranging from 400 to 1200.

Release Preparation

Depending on the level of gloss required, once the machined board has been finished to the required standard it can either be coated directly with a suitable chemical release agent (such as Easy-Lease) or it can be first sealed using a specialist board sealer before applying release agent.

When release coating the board without first using a specialist board sealer, numerous application of release agent will be required and the gloss level attainable will be limited to a satin finish.

By using a specialist board sealer, a full gloss superior surface finish can be quickly achieved. Follow the instructions for the board sealer you are using. Easy Composites' S120 Advanced Board Sealer is recommended for sealing EB700 board and can be applied by lint-free cloth or by spray. Typically, 3-4 layers of S120 Board Sealer will provide a non-porous, hard-wearing surface for a low volume production mould. Once hardened the S120 Board Sealer finish can be flatted and polished to a high gloss.

After using a suitable board sealer, a compatible release-agent, such as Easy-Lease, is required. Release agent should be applied according to the accompanying instructions.

EB700 is a high quality 700kg/m³ epoxy tooling board. This rigid epoxy tooling block is recommended for demanding applications for CNC machining of highly accurate models, patterns or masters as well as production tools/moulds.

Epoxy is the tooling board of choice for high temperature applications and is essential when making prepreg composite moulds or components where, at elevated temperature, this epoxy pattern material will not inhibit the cure of prepregs in the same way that polyurethane (PU) board will.

Typical Usese

EB700 Epoxy Tooling Board can be used to produce highly accurate patterns and moulds. Patterns can be used to produce high volume composite moulds, including using prepreg tooling systems (with cure temperatures up to 130°C) and where dimensional stability is critical.

For smaller production runs EB700 can be used to produce the working mould itself. In this situation the machined mould - once suitably sealed and prepared - can be used as a mould/tool for the production of composite parts, including the manufacture of prepreg composite components (oven-only or autoclave cure).

Advantages

- High dimensional stability (low CTE)

- High temperature use (up to 130°C)

- Compatible with epoxy tooling and component prepregs

- Can be used directly as a mould/tool, including with prepregs

- Excellent internal consistency for a high quality surface finish

How to Buy

This board is available in 2 thicknesses; 50mm (2") and 100mm (4") and a range of sizes up to 500mm x 1500mm (19" x 59"), please select the thickness and block size you require from the drop-down menu at the top of the page.

Further Information

Bonding

For larger patterns or more diverse shapes, it is often necessary to bond multiple boards together or to cut and join a board to produce a hollow 'rough shape' prior to machining. In this case, EA700 Epoxy Tooling Board Adhesive can be used to bond the tooling board, resulting in machinable bond-line which matches the density and behaviour of the surrounding board.

Finishing

EB700 can be cut and shaped by hand however it is a high density material and better suited to CNC machining. Once machining is complete, the board can be finished to an excellent satin finish using a range of abrasive papers, typically ranging from 400 to 1200.

Release Preparation

Depending on the level of gloss required, once the machined board has been finished to the required standard it can either be coated directly with a suitable chemical release agent (such as Easy-Lease) or it can be first sealed using a specialist board sealer before applying release agent.

When release coating the board without first using a specialist board sealer, numerous application of release agent will be required and the gloss level attainable will be limited to a satin finish.

By using a specialist board sealer, a full gloss superior surface finish can be quickly achieved. Follow the instructions for the board sealer you are using. Easy Composites' S120 Advanced Board Sealer is recommended for sealing EB700 board and can be applied by lint-free cloth or by spray. Typically, 3-4 layers of S120 Board Sealer will provide a non-porous, hard-wearing surface for a low volume production mould. Once hardened the S120 Board Sealer finish can be flatted and polished to a high gloss.

After using a suitable board sealer, a compatible release-agent, such as Easy-Lease, is required. Release agent should be applied according to the accompanying instructions.

Specification

Weight and Dimensions

| Thickness | 50 | mm |

|---|---|---|

| Length | 250 | mm |

| Width | 250 | mm |

Product Data

| Colour | Green | |

|---|---|---|

| Density | 700 | kg/m³ |

Compatible With

| Compatible With | Epoxy | Yes |

|---|---|---|

| Compatible With | Polyester | Yes |

| Compatible With | Vinylester | Yes |

| Compatible With | Polyurethane | Yes |

| Compatible With | RTV Silicone | Yes |

| Compatible With | Prepregs | Yes |

Mechanical Properties

| Max Service Temp | 130 | °C |

|---|---|---|

| Chemistry / Material | Epoxy | |

| Compressive Strength | 50 | MPa |

General Properties

| Gross Weight | 2.19 | kg |

|---|

Unfortunately none of our tooling boards carry any Fire Retardancy or Fire Rating certification.

To bond the boards together, you can simply use an epoxy resin as an adhesive. Brush apply a thin layer to each bonding surface, then press the two boards together and allow the resin to fully cure. Our EL2 Epoxy Laminating Resin will work very well for this purpose.

Really the EB700 is a bit on the brittle side for using as a compression mould tool so we wouldn't advise it. It might be okay for a 1 off but probably not if you were wanting to use it for multiple castings.

For most simple desktop routers a 6mm flat end mill cutter will work well for both rough cutting passes and the finishing passes.

Yes it can. It can be used for either simple moulds or more complicated multi-part moulds. It does not have the long term durability of a properly made set of pre-preg tooling or billet tool, so is more suited for one off jobs or small production runs. You also need to consider the CTE (expansion) of the board which will limit the cure temperature if you need to maintain dimensional accuracy.

You would ideally combine this board with our S120 Advanced Board & Mould Sealer to give a high quality tooling surface which, once release coated, is ready for immediate use.

No, cured epoxy such as this block is not currently recycled and as such should be treated as non-hazardous general waste for disposal considerations.

No, I'm afraid our EP700 Epoxy Tooling Block is currently only available in the green colour.

ASK YOUR OWN QUESTION

Customer Product Reviews for EB700 High Temperature Epoxy Tooling Board

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

RELATED PRODUCTS

RELATED PRODUCTS

100% SECURE

PAYMENT METHODS

Easy Composites EU B.V., registered in the Netherlands 73601195. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.