Need any help or advice?+44 (0)1782 454499

Specification

Weight and Dimensions

| Length | 540 | mm |

|---|---|---|

| Width | 505 | mm |

Product Data

| Colour | Green | |

|---|---|---|

| Max Service Temp | 80 | °C |

| Thickness | 10 | mm |

| Chemistry / Material | PVC | |

| Density (Dry) | 75 | kg/m³ |

Mechanical Properties

| Tensile Strength | 1.89 | MPa |

|---|---|---|

| Tensile Modulus | 75 | MPa |

| Compressive Strength | 1.33 | MPa |

| Compressive Modulus | 72.5 | MPa |

| Plate Shear Strength | 1.09 | MPa |

| Plate Shear Modulus | 27.7 | MPa |

| Plate Shear Elongation at Break | 20.25 | % |

General Properties

| Gross Weight | 0.225 | kg |

|---|

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

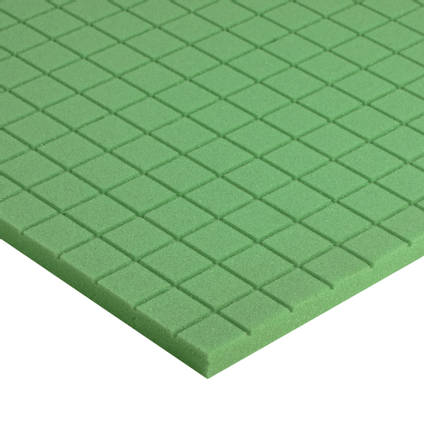

EasyCell75G Infusion Grooved PVC Foam

- PVC75G-025-10

- No reviews

Drilled and grooved version of our EasyCell 75 foam core material allows this foam core to be used as a core material in a resin infused laminate without the foam preventing resin from passing through the core to the reinforcement underneath. Drill holes allow the resin to pass easily through the foam whilst the grooves on the underside act to distribute the resin and aid flow on the underside. 75kg/m³ density.

Available in 10mm and 25mm thickness, in a range of sheet sizes.

PRODUCT VERSIONS

Sheet Size

Thickness

AVAILABILITY:More than 10 availablefor immediate shipping

Trade discounts

| 0-9 | 10+ |

|---|---|

| €13.15 | €12.05 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

75kg/m³ density closed cell PVC foam designed specifically as a structural core material grooved foam for resin infusion.

EasyCell75G 'Infusion Grooved' foam is drilled to allow resin to transfer from one side of the foam to the other and grooved on one side to facilitate the distribution of resin on the underside of the foam during a vacuum assisted resin infusion.

The 75kgs/m³ density is ideally suited to use as a core material in range of resin infused panels such as decks, bulkheads and architectural applications.

EasyCell75G is a simple core material to use. The sheet is placed with the grooves down against the mould side of the laminate. Peel ply and infusion mesh are used against the laminate on the 'open side' of the moulding where the mesh distributes the resin across the top side of the sheet before it drops down through the holes in the foam and is distributed on the mould side by the grooves in the foam.

EasyCell75G is relatively inexpensive, offers excellent mechanical performance and is compatible with all standard resin systems including polyester, vinylester and epoxy. If you're looking for a simple yet effective way to construct resin infused composite panels whilst minimising weight, cost and processing time then and cost then EasyCell75G is a great choice.

Typical Uses

As a high performance, low cost core material EasyCell75G is suitable for a wide range of application including:

- Architectural panels, cladding, enclosures

- Marine hulls, decks, hatches and floors

- Wind energy turbine blades, enclosures

- Bulkheads, floors and cabins for rail applications

Advantage:

- Designed specifically for resin infusion

- Drilled for resin transfer, grooved for mould-side distribution of resin

- Almost no resin uptake

- Almost no water absorption

- Excellent strength to weight ratio

- Good thermal insulation

- Fire retardant (self extinguishing)

- Will not rot

- Good styrene resistance

- Good impact and fatigue resistance

How to Buy

EasyCell75G is available to buy online in 1020mm x 1085mm sheets and handy 505mm x 540mm sheets. Generally, there is no problem butt-jointing multiple sheets of core material in a laminate and smaller sheets also makes them easier to handle and ship.

The foam can also be supplied in full sheet sizes of 1020x2180mm by request but shipping costs will be considerably higher.

Easy Composites are a major distributor of closed cell PVC foam and we should be able to beat any like-for-like quote. If you require larger quantities (such as full boxes) then please contact us for pricing.

Further Information

Processing

The closed cell structure means that the foam will not absorb resin (like Coremat will for example) meaning the core stays resin free, reducing the weight and cost of the finished composite.

The closed cell structure also means that PVC foam can be used in vacuum manufacturing processes it very well suited to RTM, resin infusion and vacuum bagging as well as conventional open lamination. The fine cell structure is an excellent bonding surface compatible with most standard resin systems including epoxy, polyester and vinylester.

Thickness

EasyCell75G is available in 10mm and 25mm thicknesses ideal for use in thicker sandwich panels and larger applications such as marine, rail and architectural use. The 10mm and 25mm sheets are difficult to bend with or without heat and so are generally used flat or with only a slight curvature.

Trade discounts

| 0-9 | 10+ |

|---|---|

| €13.15 | €12.05 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

75kg/m³ density closed cell PVC foam designed specifically as a structural core material grooved foam for resin infusion.

EasyCell75G 'Infusion Grooved' foam is drilled to allow resin to transfer from one side of the foam to the other and grooved on one side to facilitate the distribution of resin on the underside of the foam during a vacuum assisted resin infusion.

The 75kgs/m³ density is ideally suited to use as a core material in range of resin infused panels such as decks, bulkheads and architectural applications.

EasyCell75G is a simple core material to use. The sheet is placed with the grooves down against the mould side of the laminate. Peel ply and infusion mesh are used against the laminate on the 'open side' of the moulding where the mesh distributes the resin across the top side of the sheet before it drops down through the holes in the foam and is distributed on the mould side by the grooves in the foam.

EasyCell75G is relatively inexpensive, offers excellent mechanical performance and is compatible with all standard resin systems including polyester, vinylester and epoxy. If you're looking for a simple yet effective way to construct resin infused composite panels whilst minimising weight, cost and processing time then and cost then EasyCell75G is a great choice.

Typical Uses

As a high performance, low cost core material EasyCell75G is suitable for a wide range of application including:

- Architectural panels, cladding, enclosures

- Marine hulls, decks, hatches and floors

- Wind energy turbine blades, enclosures

- Bulkheads, floors and cabins for rail applications

Advantage:

- Designed specifically for resin infusion

- Drilled for resin transfer, grooved for mould-side distribution of resin

- Almost no resin uptake

- Almost no water absorption

- Excellent strength to weight ratio

- Good thermal insulation

- Fire retardant (self extinguishing)

- Will not rot

- Good styrene resistance

- Good impact and fatigue resistance

How to Buy

EasyCell75G is available to buy online in 1020mm x 1085mm sheets and handy 505mm x 540mm sheets. Generally, there is no problem butt-jointing multiple sheets of core material in a laminate and smaller sheets also makes them easier to handle and ship.

The foam can also be supplied in full sheet sizes of 1020x2180mm by request but shipping costs will be considerably higher.

Easy Composites are a major distributor of closed cell PVC foam and we should be able to beat any like-for-like quote. If you require larger quantities (such as full boxes) then please contact us for pricing.

Further Information

Processing

The closed cell structure means that the foam will not absorb resin (like Coremat will for example) meaning the core stays resin free, reducing the weight and cost of the finished composite.

The closed cell structure also means that PVC foam can be used in vacuum manufacturing processes it very well suited to RTM, resin infusion and vacuum bagging as well as conventional open lamination. The fine cell structure is an excellent bonding surface compatible with most standard resin systems including epoxy, polyester and vinylester.

Thickness

EasyCell75G is available in 10mm and 25mm thicknesses ideal for use in thicker sandwich panels and larger applications such as marine, rail and architectural use. The 10mm and 25mm sheets are difficult to bend with or without heat and so are generally used flat or with only a slight curvature.

Specification

Weight and Dimensions

| Length | 540 | mm |

|---|---|---|

| Width | 505 | mm |

Product Data

| Colour | Green | |

|---|---|---|

| Max Service Temp | 80 | °C |

| Thickness | 10 | mm |

| Chemistry / Material | PVC | |

| Density (Dry) | 75 | kg/m³ |

Mechanical Properties

| Tensile Strength | 1.89 | MPa |

|---|---|---|

| Tensile Modulus | 75 | MPa |

| Compressive Strength | 1.33 | MPa |

| Compressive Modulus | 72.5 | MPa |

| Plate Shear Strength | 1.09 | MPa |

| Plate Shear Modulus | 27.7 | MPa |

| Plate Shear Elongation at Break | 20.25 | % |

General Properties

| Gross Weight | 0.225 | kg |

|---|

The Highest operating temperature for our EasyCell75 Closed Cell PVC foam is 80 °C.

The PVC foam is closed cell, so technically it does not absorb any resin. In basic tests of the standard PVC75 we could not measure any resin uptake. Sure there will be a small amount of resin that fills any open cells on the cut surface of the panel but in our tests we could not measure that separate to the normal resin excess variations in hand lay up and infusion. We have calculated the volume of the grooves and the holes to be 427cm3 per square meter of theoretical resin uptake compared to the standard EasyCell 75.

Although from a technical standpoint, PVC can be cut by laser, it generates acids and toxic fumes which can damage the laser equipment and are also hazardous to health. For that reason, we would not recommend cutting PVC by laser.

Yes Rob, to both those questions. Butting sheets of core together is perfectly fine; given that the core acts almost exclusively in compression, there is really no penalty to butting multiple sheets together, this is normal practice. As for vag bagging and infusing, yes, that's what this 'drilled and grooved' version of the EasyCell is for. You position the grooves face down, they will facilitate resin distribution on the underside of the core. The drill holes let the resin pass through the sheet from the top face where you will have all the usual infusion setup; reinforcement, peel ply, flow mesh, and bag.

ASK YOUR OWN QUESTION

Customer Product Reviews for EasyCell75G Infusion Grooved PVC Foam

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

RELATED PRODUCTS

RELATED PRODUCTS

100% SECURE

PAYMENT METHODS

Easy Composites EU B.V., registered in the Netherlands 73601195. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.