Need any help or advice?+44 (0)1782 454499

Downloads (1)

| Technical DataSheet (TDS) |

Specification

Product Data

| Colour | White | |

|---|---|---|

| Format | Woven Fabric | |

| UV Resistance | Fully UV Stable | |

| Fibre Type | Diolen |

Compatible With

| Compatible With | Epoxy | Yes |

|---|---|---|

| Compatible With | Polyester | Yes |

| Compatible With | Vinylester | Yes |

Weight and Dimensions

| Thickness | 0.4 | mm |

|---|---|---|

| Consolidated Thickness | 0.4 | mm |

| Width | 960 | mm |

| Areal Weight | 265 | g/m² |

Fabric Specification

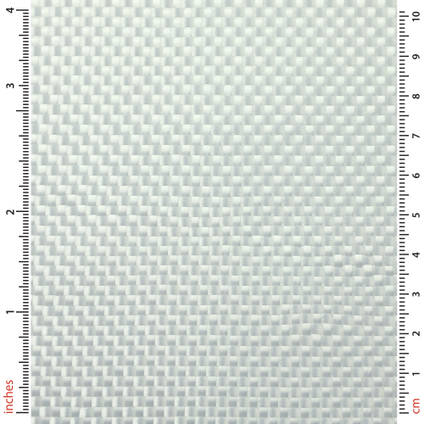

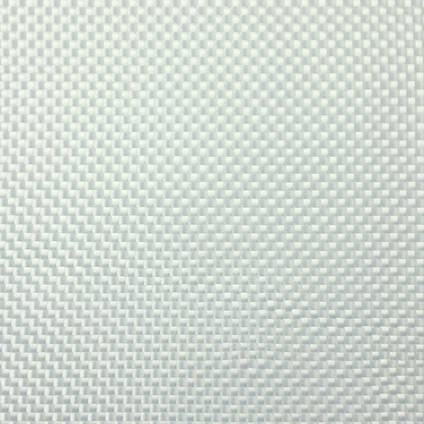

| Weave | 1 x 1 Plain | |

|---|---|---|

| Fibre Specifics | White Diolen |

Mechanical Properties

| Ends | 3.4 | cm |

|---|---|---|

| Picks | 3.4 | cm |

General Properties

| Gross Weight | 0.24 | kg |

|---|

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

265g Plain Weave Diolen Cloth (960mm)

- DL-PL-265-96

- No reviews

Diolen is a low-cost, high tenacity polyester fibre with excellent impact and abrasion properties making it a popular choice for use in high impact applications, such as canoes, kayaks and life rafts.

This natural colour, plain weave 265gsm cloth would typically be used in conjunction with glass fibre reinforcement as a cost-effective way to add impact and abrasion strength to a laminate.

This fabric is 0.96m (960mm wide) and sold by the linear metre.

AVAILABILITY:More than 100 availablefor immediate shipping

Trade discounts

| 0-4 | 5-9 | 10-49 | 50-99 | 100+ |

|---|---|---|---|---|

| €8.30 | €7.95 | €7.35 | €6.90 | €6.60 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

Diolen is a polyester based fibre, along similar lines to Kevlar which although not as strong in tensile strength as Kevlar, is reasonably close in performance (especially with regards to impact strength and abrasion resistance) and considerably cheaper.

Diolen's excellent elongation to break properties, excellent abrasion resistance and low price make it a very popular choice for kayaks, canoes, jet-skis, lifeboats and many other water going craft where impact and abrasion resistance are important but where material cost is also a consideration.

How to Buy

This 265g Diolen roll is 960mm (38") wide and the fabric is sold by the linear metre. The unit price shown is for 1 linear metre, volume discounts automatically apply for larger quantities of fabric.

Please purchase the number of linear metres you require. When purchasing multiple metres the fabric will be supplied in one continuous length on a roll.

Further Information

Using Diolen

When used in boat construction Diolen is typically combined with glass fibre (either chopped strand mat or woven glass rovings) to add considerably impact strength to an otherwise brittle and vulnerable all glass fibre construction. In this construction, tensile strength, providing stiffness, comes from the glass fibre with the high elongation to break coming from the Diolen. A hull using a combination of glass and Diolen will be far less likely to suffer major damage following a serious rock/vessel impact than an all glass reinforced boat.

Like glass, Kevlar or carbon fibre, Diolen can be used with most resin systems including polyester, vinylester and epoxy although to get the best performance from the fibre epoxy resin would always be the first choice.

Diolen will wet-out and is laminated in a very similar way to Kevlar and is totally compatible with any laminating process including wet-lay, vacuum bagging, resin infusion and RTM.

Trimming Parts Made From Diolen

Diolen's very high elongation to break properties and abrasion resistance mean that it is very difficult (and frustrating!) to trim parts made from this material. Traditional cutting tools will tend to leave a 'furry' edge which subsequently can be removed using a fine grit abrasive sanding pad.

After initial trimming (using something like a Perma-Grit wheel in a Dremel) the loose Diolen fibres can often be cut away using a very sharp Stanley knife.

Trade discounts

| 0-4 | 5-9 | 10-49 | 50-99 | 100+ |

|---|---|---|---|---|

| €8.30 | €7.95 | €7.35 | €6.90 | €6.60 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

Diolen is a polyester based fibre, along similar lines to Kevlar which although not as strong in tensile strength as Kevlar, is reasonably close in performance (especially with regards to impact strength and abrasion resistance) and considerably cheaper.

Diolen's excellent elongation to break properties, excellent abrasion resistance and low price make it a very popular choice for kayaks, canoes, jet-skis, lifeboats and many other water going craft where impact and abrasion resistance are important but where material cost is also a consideration.

How to Buy

This 265g Diolen roll is 960mm (38") wide and the fabric is sold by the linear metre. The unit price shown is for 1 linear metre, volume discounts automatically apply for larger quantities of fabric.

Please purchase the number of linear metres you require. When purchasing multiple metres the fabric will be supplied in one continuous length on a roll.

Further Information

Using Diolen

When used in boat construction Diolen is typically combined with glass fibre (either chopped strand mat or woven glass rovings) to add considerably impact strength to an otherwise brittle and vulnerable all glass fibre construction. In this construction, tensile strength, providing stiffness, comes from the glass fibre with the high elongation to break coming from the Diolen. A hull using a combination of glass and Diolen will be far less likely to suffer major damage following a serious rock/vessel impact than an all glass reinforced boat.

Like glass, Kevlar or carbon fibre, Diolen can be used with most resin systems including polyester, vinylester and epoxy although to get the best performance from the fibre epoxy resin would always be the first choice.

Diolen will wet-out and is laminated in a very similar way to Kevlar and is totally compatible with any laminating process including wet-lay, vacuum bagging, resin infusion and RTM.

Trimming Parts Made From Diolen

Diolen's very high elongation to break properties and abrasion resistance mean that it is very difficult (and frustrating!) to trim parts made from this material. Traditional cutting tools will tend to leave a 'furry' edge which subsequently can be removed using a fine grit abrasive sanding pad.

After initial trimming (using something like a Perma-Grit wheel in a Dremel) the loose Diolen fibres can often be cut away using a very sharp Stanley knife.

Downloads (1)

| Technical DataSheet (TDS) |

Specification

Product Data

| Colour | White | |

|---|---|---|

| Format | Woven Fabric | |

| UV Resistance | Fully UV Stable | |

| Fibre Type | Diolen |

Compatible With

| Compatible With | Epoxy | Yes |

|---|---|---|

| Compatible With | Polyester | Yes |

| Compatible With | Vinylester | Yes |

Weight and Dimensions

| Thickness | 0.4 | mm |

|---|---|---|

| Consolidated Thickness | 0.4 | mm |

| Width | 960 | mm |

| Areal Weight | 265 | g/m² |

Fabric Specification

| Weave | 1 x 1 Plain | |

|---|---|---|

| Fibre Specifics | White Diolen |

Mechanical Properties

| Ends | 3.4 | cm |

|---|---|---|

| Picks | 3.4 | cm |

General Properties

| Gross Weight | 0.24 | kg |

|---|

Unfortunately the Diolen fabric does not become transparent in the same way that glass fibre does when it is wetted out with resin. Although it is slightly translucent, it definitely doesn't go properly transparent and so the carbon fibre underneath would not show through properly.

However, we do stock a Black Diolen 200gsm 2/2 Twill which has the same weave pattern as a typical 200g twill carbon and is dyed black. Side by side, the diolen is fractionally darker in colour but to most eyes it looks like carbon fibre. This would give you the outer abrasion resistance you need yet still retain the carbon look.

ASK YOUR OWN QUESTION

Customer Product Reviews for 265g Plain Weave Diolen Cloth (960mm)

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

CUSTOMERS ALSO PURCHASED

CUSTOMERS ALSO PURCHASED

100% SECURE

PAYMENT METHODS

Easy Composites EU B.V., registered in the Netherlands 73601195. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.